X

[sort:name]

Technical Q&A

There are many methods for measuring the concentration of pulverized coal in the pulverized coal pipeline of power plant boilers. Some researchers have developed an isokinetic sampling method that can automatically measure the concentration of pulverized coal in the entire cross section. Although the measurement speed is faster than the method of measuring the concentration of pulverized coal by isokinetic sampling at a single point and then averaging, it is still time-consuming and labor-intensive. For the intermediate storage system, the heat balance method is used to measure the concentration of pulverized coal [1], which has been widely used in China. For the exhaust gas powder delivery system, a pulverized coal concentration measurement method based on pressure difference has been developed [2]. For the direct-blowing pulverizing system, an online pulverized coal concentration measurement method based on the principles of electrostatic method [3], capacitance method [4], optical method [5], etc. has been developed.

This paper develops a method and device for measuring the concentration of gas-solid two-phase flow in a pipe based on ultrasonic passive receiving method. The method is to install an ultrasonic receiver on the outside of the elbow of coal powder, receive the ultrasonic signal generated by the solid particles in the gas-solid two-phase flow hitting the elbow pipe wall, and transmit the signal to the computer through the amplifier. After the computer processes the ultrasonic signal, the concentration of the gas-solid two-phase flow in the pipe is obtained according to the change of signal characteristics under different solid concentrations. This measurement method is a non-contact measurement method, which can realize the continuous online measurement of the solid concentration in the gas-solid two-phase flow.

1 Working Principle

There are many elbows in the powder conveying system of power station boilers. When the gas-solid two-phase flow flows through the elbow, due to the different inertia of the gas and solid phases, the solid phase particles are thrown to the outside of the elbow by the inertia force and collide with the inner wall of the elbow. On the one hand, this collision changes the direction of movement of the particles and realizes the turning of the gas-solid two-phase flow. On the other hand, during the collision process, part of the energy is transmitted through the pipe wall in the form of sound energy. Part of this sound energy is ultrasonic wave. Ultrasonic wave with a frequency greater than 20 kHz has the advantages of good metal penetration but weak propagation ability in the air, so it is very suitable as a measurement signal.

An ultrasonic receiver is installed on the outside of the elbow wall of the powder hose. A coupling agent is used to couple the ultrasonic receiver and the pipe wall. The ultrasonic signal emitted by particles hitting the elbow wall at different solid concentrations can be measured. The signal is amplified by an amplifier and then sent to a computer through a data acquisition device. The computer performs parameter analysis on the acquired ultrasonic signal, or obtains the characteristics of the ultrasonic signal through spectrum analysis and wavelet analysis, thereby inferring the concentration of solid particles.

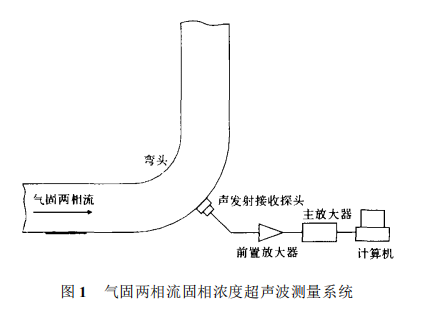

The ultrasonic measurement system for solid phase concentration in gas-solid two-phase flow is shown in Figure 1. The system uses an acoustic emission receiving sensor with a center frequency of 150 kHz, a preamplifier gain of 40 db, and a main amplifier as a multi-channel amplifier, which can amplify the 24-channel acoustic wave signal after the preamplifier, and the gain is adjustable by 1, 10, and 100 times. A PCI data acquisition card is used, with a maximum sampling speed of 20 MHz and an accuracy of 12 bits.

2 Gas-solid two-phase flow test bench

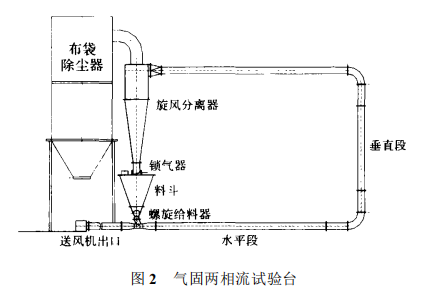

The gas-solid two-phase flow test bench is shown in Figure 2. It is mainly composed of a high-pressure fan, a spiral powder feeder, an air duct, a cyclone separator, a hopper, an air lock, a bag dust collector, etc. The system powder feeding amount is controlled by a speed regulating motor, and the maximum powder feeding amount is (2-3) t/h. The inner diameter of the powder pipe is 150 mm, the horizontal section length is 5 m, and the vertical section length is 3 m. The bending radius of the elbow between the horizontal section and the vertical section is R = 150 mm, and the pipe wall thickness is 4.5 mm.

The test bench simulates the powder conveying system of a 300 MW unit, with a modeling ratio of 1:2.708. After modeling calculation, talcum powder was selected as the solid phase material, with a density of 2700 kg/m3, an average particle size of 25 μm, and a wind speed of 25 m/s in the tube. Since the cyclone separator has a better separation effect on large particles and a poor separation effect on fine particles, the powder in the hopper will become coarser and coarser, resulting in changes in the separation effect. For this reason, the fine ash separated by the bag filter is returned to the hopper, and the material is replaced regularly. The test results show that the particle size distribution of the test material remains basically unchanged.

3. Analysis of test results

Figure 3 shows the signal waveform obtained by the acoustic emission receiver at different powder feeder speeds. As can be seen from the figure, the acoustic emission signal is a continuous signal. As the powder feed concentration increases, the signal waveform becomes very dense, indicating that the frequency of solid particles hitting the tube wall increases rapidly with the increase of solid concentration. Since the signal waveform is very dense, it is basically impossible to distinguish the signal waveform by the naked eye. It is necessary to use signal analysis methods such as spectrum or wavelet to obtain a more intuitive waveform analysis diagram. However, spectrum analysis or wavelet analysis is time-consuming and more suitable for detailed analysis afterwards. In order to facilitate on-site online application, this paper uses the acoustic emission signal parameter analysis method [6] and uses parameters such as amplitude, ring count, energy, and root mean square voltage to analyze the signals at different powder feed concentrations. The analysis results are shown in Table 1. The powder feed concentration in Table 1 is obtained by isokinetic sampling calibration. As can be seen from Table 1, the acoustic emission receiving system is very sensitive to whether there is powder in the gas-solid two-phase flow, which is manifested in the difference in signal amplitude, energy, and root mean square voltage.

During the test, the fineness of the coal powder remained unchanged. The amplitude of the signal characteristics received by the acoustic emission system represents the collision of large particles, which reflects the maximum particle size of the coal powder in a certain sense, while the ring count reflects the number of particles with greater energy. This parameter can reflect the fineness distribution of the coal powder to a certain extent. However, it can be seen from Table 1 that for the measurement of coal powder concentration, when the gas-solid two-phase flow reaches a certain concentration, it is difficult to obtain a clearer concentration resolution by using signal analysis methods such as signal amplitude and ring count, while the root mean square voltage can obtain a better resolution, which can provide a simpler and more convenient method for online in-pipe gas-solid two-phase flow concentration monitoring. This method is particularly sensitive to whether the powder is broken in the pipe, and is very suitable as a monitoring method for in-pipe powder breaking.

The solid phase concentration monitoring system of gas-solid two-phase flow in pipe based on ultrasonic receiving principle has the following advantages:

(1) It can realize online monitoring of whether the powder is broken in the pipe and realize continuous online measurement of solid concentration in gas-solid two-phase flow.

(2) This method is a non-contact measurement method. It does not require drilling a hole in the powder hose or inserting a probe into the powder hose. This reduces the workload and avoids wear or contamination of the measuring element.

(3) A computer can be used to measure multiple pipes simultaneously. As long as ultrasonic receivers are installed on multiple pipes, a computer can collect and process the signals.

(4) Not affected by factors such as on-site noise.

(5) It can be widely used in the field of pneumatic conveying and can be easily implemented on pipelines with elbows.

4 Conclusion

The method of measuring the concentration of gas-solid two-phase flow in a pipe based on ultrasonic passive absorption is a non-contact measurement method that can realize continuous online measurement of solid concentration in gas-solid two-phase flow. Since the measurement of gas-solid two-phase flow is very complicated, this paper is only an exploration of this new measurement method. Preliminary research has proved the feasibility of this method, and there is still a lot of work to be done. How to use advanced signal analysis technology to improve the resolution of the signal is an important content to be studied in the next step of this topic.

[ references]

[1] Wang Kai, Zhao Haisheng, Chen Zenghong. Coal powder concentration monitoring system[J]. Power Engineering, 1994, 14(3):45-48.

[2] Wu Baohui, Shi Jianbin. Research on the measurement technology of wind speed and pulverized coal concentration in exhaust gas pulverized coal boiler[J]. Thermal Power Generation, 2002, 31(3):21-24.

[ 3] J. Ma , Y. Yan. Design and implementation of electr ostatic sensors for the measurement of velocity of pneumatically convection eyed so lids[ J] . Flow measurement and Instrumentation 2000 , 11(4):195 204.

[4] Y. Yan, AR Reed. Experimental evolution of capacitive transducers for fluid concentration measurement of particulate solids[J]. Flow measurement and Instrumentation 1999, 10(1):45-49.

[5] Cai Xiaoshu, Pan Yongzhi, Ouyang Xin, et al. Research on the diagnosis of coal pulverized operation status in power plant coal pulverized pipelines[J]. Proceedings of the CSEE, 2001, 21(7):8386.

[6] Shen Gongtian, Geng Rongsheng, Liu Shifeng. Parameter analysis method of acoustic emission signal[J]. Nondestructive Testing, 2002, 24(2):72-77.