Pick to: in order to understand the use different stress paths in the process of cyclic loading, the characteristics of the rock acoustic emission Kaiser effect using rock failure process analysis software (RFPA2D) of three kinds of the acoustic emission features of rock specimens under different stress path has carried on the numerical calculation. In cyclic loading in different stress paths on sample loading, still in the process of secondary load can be observed clearly Kaiser effect, but with previous KF value has a big difference, the maximum stress value of the research results show that the rock the real content of Kaiser memory not previously by the maximum stress, but the inside of the rock damage degree, sampling, in use from the original rock acoustic emission experiment of uniaxial compression in laboratory do the observation method of KF value measured stress value and the real original rock stress have bigger difference, the conclusion for the further understanding of the essence of Kaiser effect and accurate determination of the original rock stress by using Kaiser effect has important role.

Key words: acoustic emission; Kaiser effect; Stress path; Numerical experiments. The original rock stress

In 1953, the German Kaiser, first of all, scientists discovered that a metal material in the acoustic emission in the process of loading with irreversible phenomenon [1], namely to repeated loading of materials, only load to material previously by the maximum load, just can have obvious acoustic emission, material of this kind of phenomenon is known as the "memory" Kaiser effect. In 1963, Goodman found in rock material is through the experiment the Kaiser effect. Since then, the Kaiser effect because of its can intuitively show the memory capacity of the rock and attention, and been widely should be

Used for testing the original rock stress.

Rock mechanics essence of acoustic emission Kaiser effect is affected by load after internal damage increases (new micro cracks or original micro crack extension), reload, only after that was the biggest load new damage will expand, new Kaiser effect of rock of the memory of the external environment, and its essence is the rock damage degree of memory of oneself, it explicitly expresses the failure process of rock material is not reversible.

In when the original rock stress is measured by the Kaiser effect, often used method is to take on the original core on the direction of six or nine specimens, the acoustic emission experiments of uniaxial compression in laboratory, and measured the Kaiser effect of each sample point stress, so stress value as the maximum stress on the direction of the sample, and then with the theory of elastic mechanics and environment around the core original rock stress. However, when using this method to test the sample is out of the original geological environment, the literature suggests that caused by the different stress path of rock damage degree is not the same. Laboratory of rock specimen under uniaxial compression and the sample of the original rock stress is clearly not the same stress path, so the uniaxial compression stress is measured point of Kaiser effect of samples in the original geological environment in the direction of the maximum stress is questionable.

Therefore, in this paper, application of rock failure process analysis software (RFPA2D), using different stress path of rock specimen cyclic loading, in order to investigate the influence of different stress paths of Kaiser effect. About the specific way of using the RFPA, function and principle of literature.

1 set numerical model

In this paper, by using the plane stress model, the size of the sample is 100 mm x 50 mm, model is divided into 200 x 100 units. Set the sample mechanical properties (elastic modulus and strength) obey Weibull distribution 2 experimental results and analysis

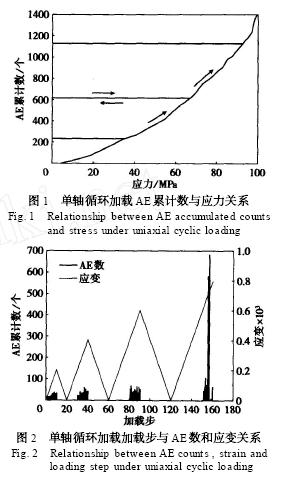

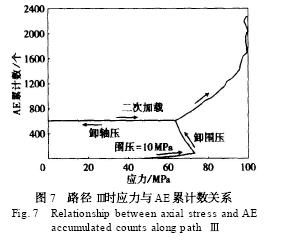

In order to know more clearly the influence of different stress paths on the Kaiser effect, first of all to the simplest sample under uniaxial cyclic compression experiment, the AE accumulative frequency and stress curve (figure 1), and load the number of steps and the strain and acoustic emission (AE) diagram (figure 2), and real experiment results fit well. From figure 1, figure 2, you can see, uniaxial cyclic loading conditions, can be clearly observed the Kaiser effect, and the Kaiser effect very accurate memory of sample previously, the maximum stress is Felicity ratio (FR) is equal to 1.

2. The selection of loading paths

According to the function of the software itself and combining with the actual situation of Kaiser effect test stress, choose three loading paths:

(1) the first loop uniaxial load, displacement control, each step load of 01002 mm, loading to 0106 mm after unloading, the secondary load and confining pressure (respectively, 5, 10, 15, 20, 30 MPa), axial loading process is the same as the first cycle, load to the sample, the loading path to path Ⅰ;

(2) the first cycle of conventional triaxial loading (confining pressure respectively, 5, 10, 15, 20, 30 MPa), the axial displacement of the load control, each step load of 01002 mm, loading to 011 mm after unloading, the secondary load using uniaxial load, loading the damage to the sample, the path to path Ⅱ;

(3) the first cycle of conventional triaxial loading, the same as the first cycle path Ⅱ, unloaded first unloading confining pressure, each step 015 MPa, and then discharge axial compression, the secondary load is still using uniaxial load, loading the damage to the sample, the Ⅲ · path to path

2 the result of the experiment 2.

(1) path Ⅰ

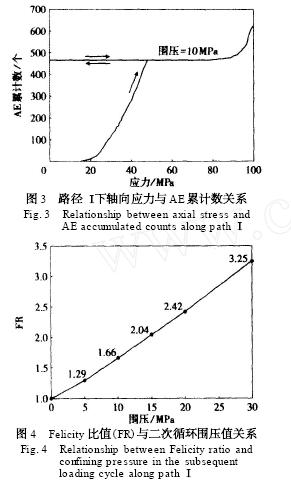

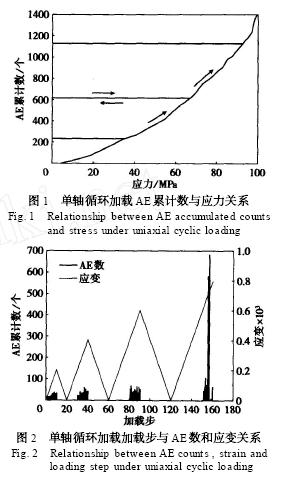

As can be seen from the figure 3, the secondary load and confining pressure, the stress of the Kaiser effect point value (hereinafter referred to as the KF value) appear obvious hysteresis, and the greater the confining pressure KF value more lag. Figure 4 shows the Felicity ratio as the secondary load increases with the increase of confining pressure value, but almost all FR under different confining pressure in a straight line.

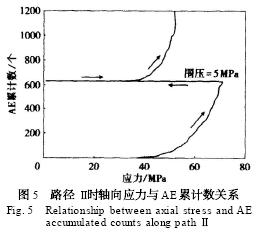

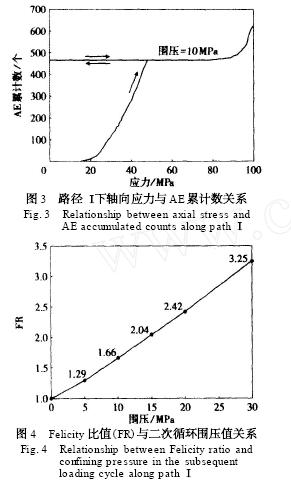

(2) path Ⅱ

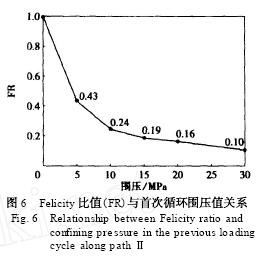

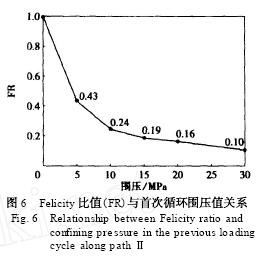

The loading paths with the Kaiser effect when the original rock stress measurement is similar to the sample under the stress path of. Is shown in figure 5, the secondary load due to discharge the confining pressure, KF value appear obvious advance phenomenon, namely the uniaxial compression than previously measured KF value maximum stress in the presence of confining pressure load, and the influence of confining pressure on KF value is very large. As shown in figure 6, the first 5 MPa confining pressure is added when loading, the measured values of KF is only 43% of that in the previous maximum stress (FR = 0143), the greater the confining pressure, the greater the impact on FR value, when the confining pressure reached 30 MPa, measured FR value is only 0.10.

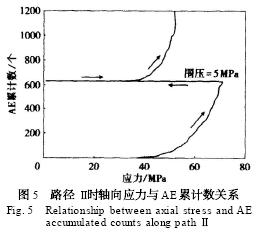

(3) path Ⅲ

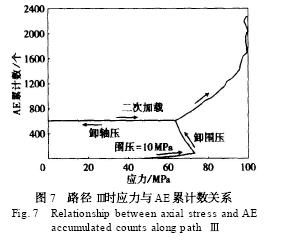

Figure 7 shows, in keeping the axial deformation under the condition of unloading confining pressure, axial stress is reduced, while internal micro cracks continue to produce and extension, but the sample is characterized by acoustic emission number continues to increase. Secondary load using uniaxial compression, KF value and unloading confining pressure in the first cycle of axial stress is equal to zero, and is not equal to the sample previously by the maximum axial stress.

2. 3 the results analysis

From the above results, the stress of the specimen under different load path, Kaiser effect the accuracy of the memory previously maximum stress affected by a lot.

First, under the loading paths Ⅰ, due to the secondary load and the confining pressure, to make the previous continue to expand the cracks must be more than any previous maximum load, so the recovery of acoustic emission appear lag phenomenon. And when the path is Ⅱ, vice versa, because of the protective first loaded with confining pressure, the appearance of the micro cracks and expand need bigger than uniaxial loading of the axial stress, secondary load time remove the confining pressure, so in had not reached the maximum axial stress of previously have AE events occur, the recovery of acoustic emission phenomenon in advance.

Path Ⅲ loads, in keeping the axial strain unloading confining pressure, axial stress decreases gradually, while the sample continue to damage, increase number of acoustic emission. Secondary loading and unloading confining pressure in the first cycle of KF value axial stress is equal to zero, obviously the Kaiser effect is not the maximum axial stress of memory, but in the process of the sample in the first cyclic loading is one of the biggest damage.

Conclusion from the above results and analysis, the samples with different stress path of cyclic loading, the process of loading can be observed a similar "Kaiser effect", but the Kaiser effect of memory is not previously by the maximum stress of sample, and is considered the biggest damage degree, the inside of the sample figure 7 is very vividly expressed the phenomenon.

3 conclusion and discussion

By using RFPA2D software of rock specimen under three different cyclic stress path of the acoustic emission characteristics of the numerical experiment, found that the sample has been different stress path load time, still in the process of secondary load can be observed clearly "Kaiser effect", but the maximum stress value of the KF value is not the same as the previous. So the real content of Kaiser effect memory not previously by the maximum stress of rock but the inside of the rock damage degree, from figure 3, figure 5, figure 7 can be clearly observed this phenomenon, the further test

The essence of the card to the Kaiser effect.

So far, the largest use of Kaiser effect is used to measure the original rock stress. According to the experimental results under the loading paths Ⅱ, using sampling from the original rock and uniaxial loading measurement KF value method in the laboratory measured results and the real original rock stress value has great difference. To accurately determine the original rock stress, must be reproduced in the laboratory sample previously by the stress path, and this is not operating. As mentioned earlier, Kaiser memory is the inside of the rock damage degree, so how to use the laboratory measured from the Angle of the rock damage speculated that the real KF value of the original rock stress, is the use of Kaiser effect accurate determination of the original rock stress must solve the issue.

References (abbreviated)